Design and Build Details

Share

Order of the Oak cabinet designs focus on practical sizing, optimal sound quality, and lifetime durability. Practical sizing focuses on a cabinet that is usable, sensible and makes efficient use of materials in the build. Optimal sound quality focuses primarily on the following three considerations:

-Optimal internal volume for improved frequency range.

-Thoroughly sealed enclosures for better speaker performance

-Joinery and construction techniques that allow the cabinet to resonate as a single unit.

Lifetime durability focuses on making sure the cabinet remains structurally rigid and uncompromised for a lifetime of use, never develops rattles or weakened joints and parts subject to wear or damage can be accessed and repaired- i.e. grill cloth, speakers, etc.

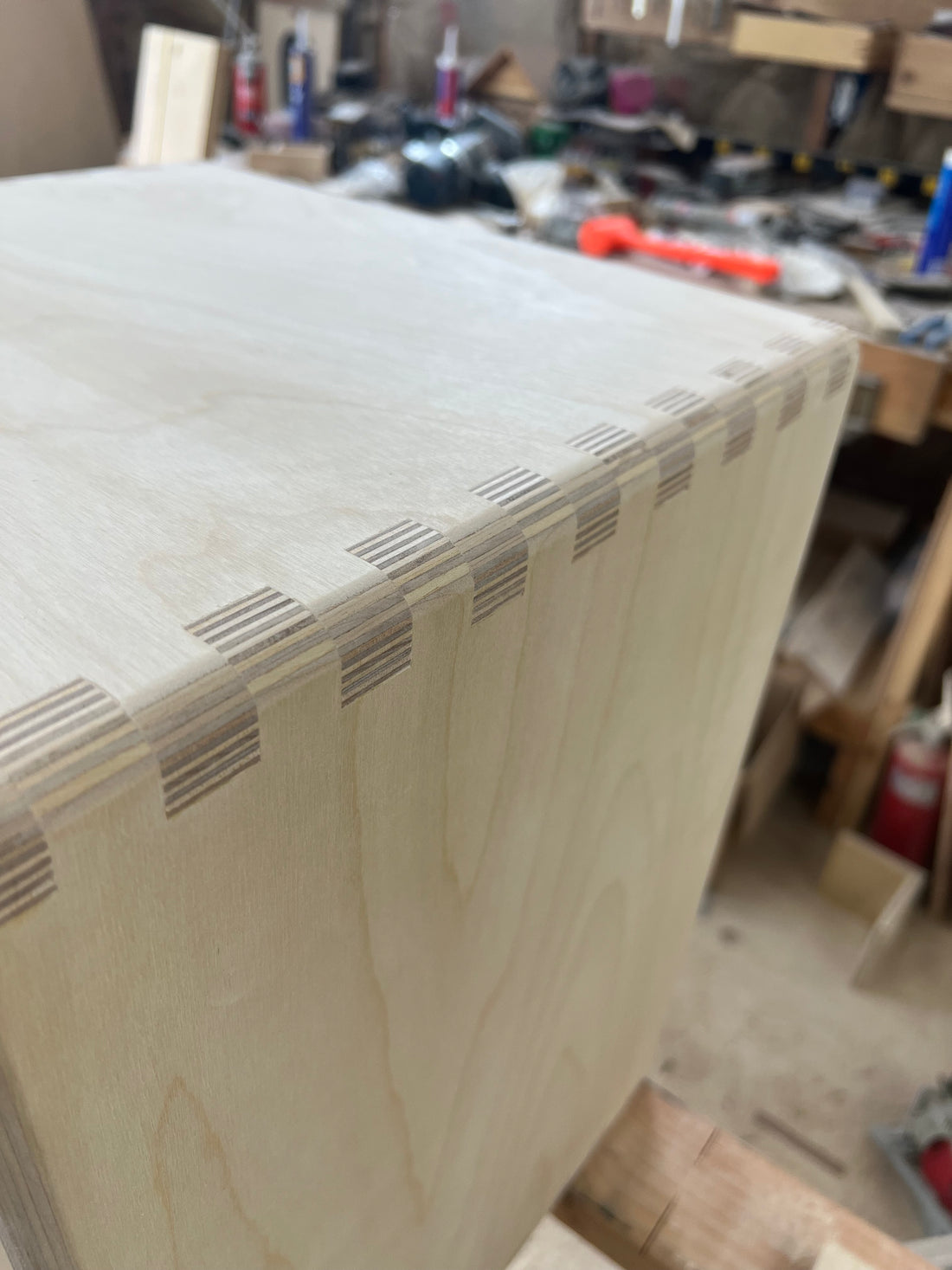

Unless otherwise noted, all cabinets are built with ¾” (18mm, 13 ply) void free baltic birch plywood to balance strength, resonance and weight. Cabinet boxes are joined with precision fit box joints. Front and rear baffle stops are glued in ¾” material. All speaker baffles are permanently glued in to add strength and to allow the cabinet to resonate as a single piece. Rear mounted speaker cabinets with removable back panels feature a gasket on the bracing and adequate fasteners to insure an airtight seal and structural integrity. Front mounted speaker cabinets have a sealed back panel glued into place. Internally, all corners and joints are sealed with silicone. Larger cabinets include front to back baffle bracing to increase rigidity and to ensure that resonance between the speaker baffle and the back panel remains in phase and uniform. Grill cloth is mounted to a separate and easily removable frame that can be mounted via screws through the speaker baffle on rear mount cabs or face mounted screws with finish washers on fully sealed cabs. Many cabinets attach the grill cloth directly to the speaker baffle. My design requires the baffles to be permanently glued in to unitize the cabinet components, making it impractical and not replaceable to attach the grill cloth directly to it. The removable frame means it is easy to replace or to take it out to paint a design or do whatever you want without the cumbersome (and in this case impossible) task of having to remove the speaker baffle.

Metal reinforced corners and rubber feet come standard on all cabinets. Optional dual parallel jacks are available at no charge on most cabinets. Recessed metal handles are standard on 4x12 cabinets and larger. Smaller cabinets are available with folding flush mount handles or top mounted carry handle. Jacks are high quality open frame switchcraft metal jacks and wiring is heavy 12 gauge stranded speaker wire. Rear mount cabinets include permanent standard spaced mounting lugs so you can quickly hang a speaker in place and tighten down the nuts and lock washers when changing speakers. Front mount cabinets use t-nuts mounted to the rear of the baffle with speakers mounted using machine screws and lock washers. Larger cabinets are available with tilt back casters and rear mount handles.